Explosion Protection Systems

WES-CO Industries helps businesses mitigate the risk of industrial process explosions. Effective management of explosion risks requires a complex understanding of not only dust and vapor characteristics, but core industry processes, relevant code compliance, economic concerns and your specific ongoing business goals.

As an authorized partner of REMBE Safety + Control products, we provide our customers with consultation, engineering, design and service for all of REMBE®’s explosion protection and process safety products.

We have engineered and installed Explosion Protection Systems that are designed to address the numerous possibilities related to industrial process explosions. We conduct a dust hazard analysis (DHA), as required by National Fire Protection Agency (NFPA), prior to designing any dust collection systems to ensure all NFPA guidelines for public safety are met.

Preventing Explosions of Combustible Dust

Industries that handle combustible dusts or gases are always at risk of an explosion. The amount of heat and high pressure that is generated during an explosion can cause disastrous damage, injury to personnel, damage to process equipment and loss of production.

Combustible dust is any fine material that has the ability to catch fire and explode when mixed with air. Combustible dusts can be from:

most solid organic materials (such as sugar, flour, grain, wood)

many metals

some nonmetallic inorganic materials

Some of these materials are not normally combustible on their own, but they can burn or explode if the particles are the right size and in the right concentration.

The Occupational Safety and Health Administration (OSHA) in the United States defines combustible dust as "a solid material composed of distinct particles or pieces, regardless of size, shape, or chemical composition, which presents a fire or deflagration hazard when suspended in air or some other oxidizing medium over a range of concentrations".

View this list of products and materials in dust form that have potential to combust.

Types of Explosion Protection Systems

Explosion protection system can include any combination of the following systems and components:

Explosion Detection

Explosion Detection systems are designed to recognize possible danger signs and activate explosion isolation and/or explosion suppression systems, effectively preventing an explosion from damaging your equipment and facility.

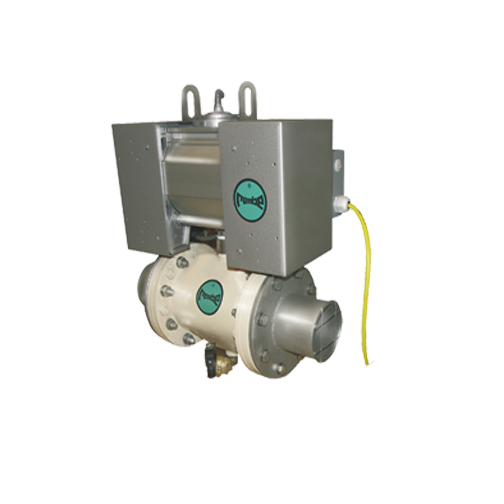

Explosion Isolation

Explosion Isolation systems prevent the propagation or spread of flame from one part of the process to another through the use of explosion isolation valves and barriers.

Explosion Venting

Explosion Suppression

Explosion venting is one of the most common and effective forms of explosion prevention and protection. Proper venting dissipates pressure and protects against potential industrial explosion hazards by providing planned pathways for expanding gases to escape.

Suppression systems are designed to detect, damper and chemically suppress an explosion in its earliest stages-before an explosion can cause greater damage or danger.

NFPA-Compliant Systems

The NFPA has established guidelines to minimize the risk of fire and threat to public safety in commercial and industrial workspace. All WES-CO Industries systems are designed and built to be compliant with the following NFPA codes:

NFPA 61 Standard for the Prevention of Fires and Dust Explosions in Agricultural and Food Processing Facilities

NFPA 68 Standard on Explosion Protection by Deflagration Venting

NFPA 69 Standard on Explosion Prevention Systems

NFPA 91 Standard for Exhaust Systems for Air Conveying of Vapors, Gases, Mists, and Particulate Solids

NFPA 96 Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations

NFPA 652 Standard on the Fundamentals of Combustible Dust

NFPA 654 Standard for the Prevention of Fire and Dust Explosions from the Manufacturing, Processing, and Handling of Combustible Particulate Solids

NFPA 664 Standard for the Prevention of Fires and Explosions in Wood Processing and Woodworking Facilities

Contact Us - we promise a prompt reply

Meet your WES-CO Representative today: EMAIL at sales@wescoindustries.com or CALL at 510.534.3320